Enterprise-ready embedded development: How IAR supports modern security policies

Security, Developer efficiency

Automotive

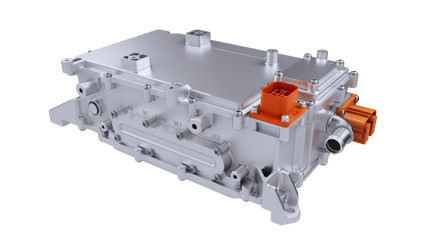

LeadDrive, a leader in dual-motor controllers for NEV powertrains, faced challenges when transitioning from global MCU suppliers to Chinese domestic platforms. By collaborating with SemiDrive and IAR, LeadDrive combined the strengths of SemiDrive’s high-end automotive-grade MCUs and IAR’s proven development solutions to accelerate the adoption of domestic MCU platforms in the automotive industry.

LeadDrive focuses on NEV powertrain R&D, delivering integrated e-drives, power modules, and power/chassis domain controllers to both domestic and global OEMs. The company has achieved miniaturization, cost optimization, and functional safety compliance while successfully transitioning to Chinese MCU platforms. Backed by strong R&D and testing capabilities, LeadDrive continues to set industry benchmarks.

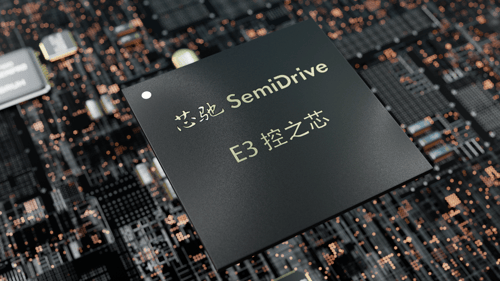

As high-end Chinese automotive MCUs emerged, LeadDrive selected SemiDrive’s E3 MCUs after thorough evaluation. This MCU-level migration required a high-performance toolchain from IAR to enable smooth adaptation and efficient development. LeadDrive integrated MCAL drivers, ported platform code, and ensured compute optimization and functional safety compliance. China’s tight “time-to-market” cycles made toolchain performance, compatibility, and local support critical for mass production. Adaptability, certification readiness, and service quality were equally essential for success.

SemiDrive’s E3 MCUs, built on Arm Cortex-R (R5/R52+) cores, target critical automotive applications with strong compute performance, real-time capability, and ASIL-D functional safety. As an early partner, IAR provides optimized toolchains, functional safety certification support, and localized services. Together, IAR and SemiDrive have enabled multiple customer projects, paving the way for broader adoption of Chinese high-end MCUs in safety-critical domains.

“Through long-term cooperation with IAR, we have delivered reliable toolchain support and localized services for customer development on the E3 platform. The success with LeadDrive showcases the reliability and value of Chinese high-end automotive MCUs in demanding applications. SemiDrive and IAR will continue to collaborate closely on ecosystem development, toolchain optimization, and functional safety compliance, building a sustainable automotive ecosystem.”

— Zhang Xitong, GM for MCU Product Line, SemiDrive

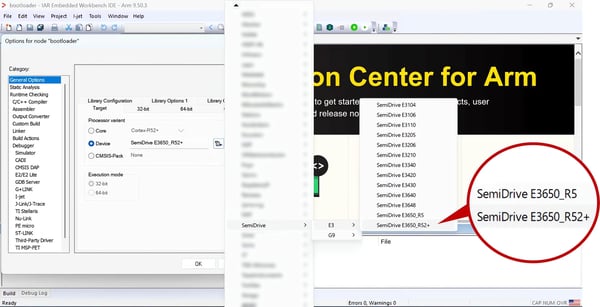

When LeadDrive evaluated a new project with SemiDrive in 2022, it selected the IAR platform for several core reasons:

IAR Embedded Workbench for Arm (Functional Safety edition) served as the core toolchain for LeadDrive’s SemiDrive E3 projects. The IDE’s full functionality and integrated code analysis tools helped detect defects early, significantly improving software stability.

Together with SemiDrive’s MCAL drivers, IAR provided lifecycle support, including technical Q&A, version guidance, and training, ensuring deep toolchain integration with LeadDrive’s software architecture and smooth mass production. This “tools + MCU + application” collaboration accelerated the adoption of Chinese MCU platforms in NEV dual-motor controllers.

LeadDrive praised IAR for outstanding tool performance, leadership in functional safety compliance, and a highly professional, responsive local support team that solved development issues efficiently.

“Working with SemiDrive and IAR has been a strategic move for our technology upgrades and for staying competitive in a fast-moving market. IAR provided a stable, high-performance toolchain and, with its strong ecosystem adaptation, enabled seamless migration and rapid development on SemiDrive’s MCU platform. The professional, responsive local service team greatly improved our efficiency and problem-resolution speed. Looking ahead, we will move beyond single-tool procurement toward joint technology development, ecosystem co-creation, and shared compliance—addressing industry challenges together with intelligent toolchains and flexible commercial models.”

— Yu Hao, Chief Software Engineer, LeadDrive

By combining SemiDrive’s powerful MCUs with IAR’s certified toolchains and local expertise, LeadDrive turned a complex migration into a clear competitive advantage. The collaboration delivered clear, measurable outcomes:

“IAR is committed to driving innovation in automotive development. We see a growing need among OEMs and Tier-1 suppliers for platform-based toolchains that combine project management, code editing, compiling, debugging, and functional safety certification in a single workflow. LeadDrive’s success with IAR’s functional safety solution is a strong showcase for the industry. We will continue investing in this area to help more companies tackle complexity and safety challenges, and to co-create a robust development ecosystem with our partners.”

— Kiyo Uemura, APAC Vice President, IAR